Doing this project and using this cartridge can be a little detail oriented. It requires more attention to detail than the 120 cartridges.

Download the 3D files here and print each of the files using supports and 3 top and bottom layers for light tightness. You can also send the an STL file with all the pieces to any print service (try Craftcloud3d for a pretty good quote in your area), or you can order them from PCBWAY which quotes around $38US for this project.

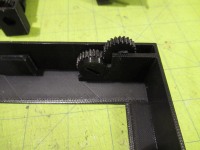

Insert the drive gear in the upper left of the cartridge. It'll install with a gentle snap. Mount the thumb gear in the two holes to the right of the drive gear with a small screw or pin (an old Polaroid hinge works) and be sure it turns the drive gear easily.

File the ridges and uneven surfaces (from the supports) off the roller ends and sand the right roller with 100 grit sandpaper to give it some friction so the film won't slide over it, instead causing the roller to roll while the film is being advanced. Snap the left roller into place. It's a tight fit so do this with care to avoid breaking anything. Clearances are small since alignment of the film over the film mask is critical. Insert the top end of the right roller into the pressure plate, then insert the shaft of the small 13 tooth gear through the hole of the pressure plate counter box into the roller end. You may want to verify that the shaft will insert snugly before installing it, but be careful not to break the shaft. If you filed down the shaft too much so it slips in easily, use some glue to secure the shaft inside the roller. Center the gear inside the gear counter box.

Mount the exposure indicator gear above the counter gear with a pin or screw, being sure it engages OK and doesn't jump gears or bind. If it is not aligned correctly, raise/lower the gear by rounding out the shaft holes in the pressure plate, then melt in place. Test the counter gear by rolling the right roller and seeing whether it engages freely, but doesn't jump off the counter gear.

Remove the original back door by removing the hinge (you may have to remove the plastic pieces at both ends of the hinge) and install the new door. It may be tricky to align the hinge while inserting it. It would be best to insert the hinge pin into the 3D printed door before installing it, to ensure the print left enough room for the hinge. Close the door while pressing on the release latch and be sure the latch engages securely. If the latch doesn't seem to return freely, file a bit off of the bottom and tip of the latch hooks on the back. Be careful as the hooks are somewhat fragile. You can either cut/glue a red filter over the film counter hole, or you can place a piece of black tape over it to prevent light leaks through the exposure counter hole.

Line the top edge of the film compartment with 2mm black craft foam to prevent light leaks from the top of the door. Alternatively, you can glue a piece of craft foam onto the outside of the cartridge, butting it up to the top of the film bay while it's installed in the camera.

An empty 35mm canister is used to takeup the film instead of rewinding it back into the original cartridge. The alleviates the need for a rewind knob.

Feel free to contact me with any questions or news about your build!