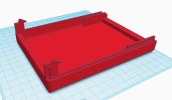

By far the easiest way to get started with film holders is to download this file and print them on a 3D printer. Cut some dark slides out of black vinyl material such as folio covers. Glue some black felt at the entrance to the film holder on each side, then slide the dark slides into the film holder grooves. Push the end piece over the felt end--you may have to tap it a bit since it's a tight fit. Make sure it slides right to the end stop. Avoid pulling the dark slide all the way out. It helps seal out light and may be difficult to put back in.

Remove the pack retainer/light trap at the right side of the film bay by removing the 2 small philips screws.

You will need to adjust the rangefinder to compensate for the 1.5 or so millimeter film plane offset introduced by the film holder. Remove the cover of the rangefinder and use small pliers to turn the square shaped screw to adjust. Open the back and place a ground glass (or a piece of fogged plastic) with the same offset as the film holder into the film bay. Focus on a closer object on the ground glass and compare it to the rangefinder. Adjust the rangefinder until the images line up on the object you are focusing on. After this is done, technically the camera won't focus on infinity but you will be able to get subject in focus by selecting a smaller aperture such as f/17.5.

To load, pull the dark slide back and curl the negative and fit it into both sides of the holder. Flatten the negative at the far end of the holder and push it into the end under the groove. Once it stops, the end of the negative near the opening can be lowered into place into the grooves and flattened out. Push the dark slide in. You may want to practice this in daylight before attempting in the dark. To remove the negative, take a knife blade and slip it under the negative near the opening and lift/curl the negative upwards and pull it out.

To install the back, remove the hinge from the camera back. You will have to remove the 2 black hinge covers. They will likely break when attempting to remove them. If they do, push a thin rod into the hinge and push out the other black plastic hinge cover. Then using the same tool, push the other side of the hinge until the other hinge cover comes out and push the hinge out.

You can either permanently modify an existing back or swap it with a 3D printed one. If you have a spare back or are committed to using film holders, I would advise you to modify a Polaroid back permanently. It will give you a back that matches the camera, and will be much more durable than a 3D printed one. The back will opened and closed a lot when using film holders. If you'd rather print up a back, skip this next section.

Download the STL files here and print it up with supports and 20% or higher infill. The locking tabs may need some filing to fit perfectly, both the flat surface that locks and both edges to fit inside the latch. The hinges were made exactly to spec, so they may need filing due to printing inaccuracies. The door needs to put some pressure on the film holder when closed, but not too much pressure or things will break. Use foam on the inside of the door for this, but be aware of excess pressure on the hinges and latching mechanism.

The weak points of the door are the locking mechanism and the hinges. Be sure not to latch the door just by pushing it closed. Unlatch it on the camera, push the door closed, and release the latch. And be sure there is minimal pressure on the hinges when closing. If you break a locking tab, don't despair. I repaired mine by heating up a straight pin and sinking it into the PLA, joining the broken tab to the main base. PLA is weldable with a metal pin and lighter. You can add material if needed and form the plastic around the pin. The excess pin can be cut off with a dremel.

The camera is now ready to use a film holder. You can either make a film holder from scratch, make one from parts, or print the whole film holder. Jump to the section that pertains to you.

A home made holder is good if you don't have access to a 3D printer and want to try film holders. The downsides are that it is labour intensive and getting all the clearances correct and the dark slide sliding well is a challenge. Also, it is almost impossible to make a film holder which is able to hold a Polaroid sized negative. There is not enough clearance on the edges when using book board for rails. You will need to cut the negative slightly more narrow than a Polaroid print.